In this article, we will discuss how to fix a lifter tick in a 5.3 engine. If you own a vehicle with this engine, you may have experienced the annoying sound of a lifter tick. It can be quite bothersome, but fortunately, it is a problem that can be resolved. In this guide, we will cover the different aspects of the lifter tick, the tools you will need for the repair, safety precautions to take, a step-by-step guide to fixing the issue, and post-repair steps and maintenance.

Understanding the Lifter Tick in a 5.3 Engine

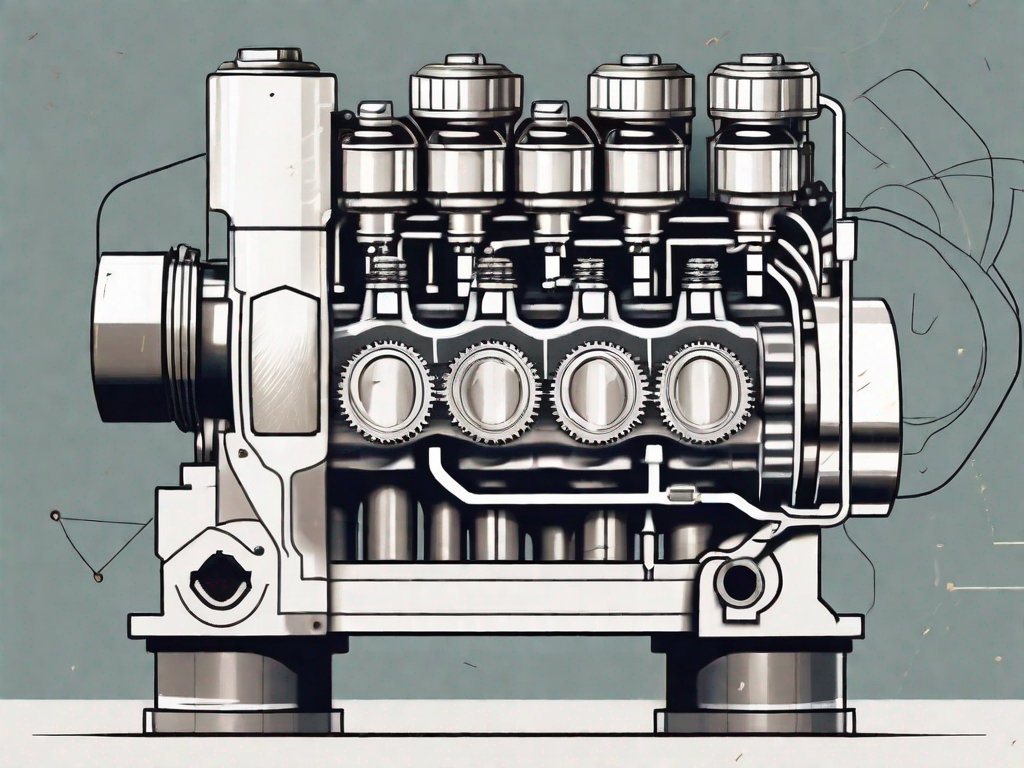

The first thing we need to do is understand what exactly is causing the lifter tick in a 5.3 engine. The lifter, also known as the tappet, is an important component of the engine. It is responsible for opening and closing the valves in the cylinder head. When the lifter becomes worn or damaged, it can produce a ticking sound. This sound is often more noticeable when the engine is cold or at idle.

The Role of the Lifter in an Engine

Before we delve deeper into the causes of lifter tick, let’s discuss the role of the lifter in an engine. The lifter is a crucial part of the valve train system. It acts as a bridge between the camshaft and the valve. As the camshaft rotates, it pushes the lifter, which in turn opens and closes the valve. The lifter must be in good condition for the valves to operate correctly.

When the lifter is functioning properly, it ensures that the valves open and close at the right time, allowing the air-fuel mixture to enter the combustion chamber and the exhaust gases to exit. This precise timing is crucial for the engine’s performance and efficiency. Without a properly functioning lifter, the engine may experience a decrease in power, fuel economy, and overall performance.

In addition to its role in valve operation, the lifter also helps maintain proper valve clearance. Over time, the valves and valve seats can wear down, causing the gap between them to increase. This can lead to a loss of compression and engine performance. The lifter compensates for this wear by adjusting its position, ensuring that the valves maintain the correct clearance.

Common Causes of Lifter Tick

Now that we understand the role of the lifter, let’s explore the common causes of lifter tick in a 5.3 engine. One of the main causes is a lack of lubrication. The lifter depends on a constant supply of oil to function properly. If the oil becomes dirty or low, it can cause the lifter to become noisy. Regular oil changes and using the recommended oil viscosity can help prevent this issue.

Another common cause of lifter tick is worn or damaged lifters. Over time, the lifter can wear down due to the constant friction and stress it experiences. This wear can lead to a ticking sound as the lifter moves within its housing. Regular maintenance, including inspecting and replacing worn lifters, can help prevent lifter tick.

Additionally, excessive engine heat can also contribute to lifter tick. When the engine runs hot, it can cause the lifter to expand, leading to increased clearance between the lifter and other components. This increased clearance can result in a ticking sound. Ensuring proper cooling system maintenance, such as regular coolant flushes and monitoring the engine temperature, can help prevent lifter tick caused by excessive heat.

Furthermore, a faulty hydraulic lifter can also be a cause of lifter tick. Hydraulic lifters use oil pressure to maintain proper valve clearance. If the lifter’s internal components wear out or the oil passages become clogged, it can result in lifter tick. In such cases, replacing the faulty lifter is necessary to eliminate the ticking sound.

In conclusion, understanding the causes of lifter tick in a 5.3 engine is essential for maintaining the engine’s performance and longevity. Regular maintenance, including proper lubrication, inspection, and replacement of worn components, can help prevent lifter tick and ensure smooth and quiet engine operation.

Essential Tools for Fixing a Lifter Tick

Before you begin the repair, it’s essential to gather the necessary tools. Here are some tools you will need:

Basic Automotive Tool Kit

Having a well-equipped automotive tool kit is crucial when it comes to fixing a lifter tick. This kit should include a variety of tools that will help you tackle the task with ease. Among the essential tools you should have are:

- Screwdrivers: A set of screwdrivers with different sizes and types will come in handy for removing various components and accessing hard-to-reach areas.

- Socket set: A socket set with different sizes and extensions is essential for loosening and tightening bolts and nuts throughout the engine.

- Pliers: Pliers will be useful for gripping and manipulating small parts, such as clips and wires, during the repair process.

- Wrenches: A set of wrenches, including both open-end and box-end wrenches, will enable you to loosen and tighten fasteners of different sizes.

- Oil filter wrench: Since you’ll be working on the engine, having an oil filter wrench will make it easier to remove and replace the oil filter.

Specialized Tools for Engine Work

In addition to the basic automotive tool kit, there are some specialized tools specifically designed for engine work that will greatly assist you in fixing a lifter tick. These tools include:

- Lifter removal tool: A lifter removal tool is a specialized tool that allows you to safely and efficiently remove the lifters from the engine. This tool ensures that you don’t damage the lifters or other engine components during the removal process.

- Valve spring compressor: When working on the lifters, a valve spring compressor is essential for compressing the valve springs and removing the valve keepers. This tool makes it possible to access and replace the lifters without having to disassemble the entire cylinder head.

- Feeler gauge: A feeler gauge is a precision measuring tool that helps you set the correct valve lash or clearance. This tool ensures that the lifters are properly adjusted, preventing any ticking noises caused by improper valve clearance.

By having these specialized tools in your arsenal, you’ll be well-prepared to tackle the lifter tick issue and restore your engine’s smooth operation.

Safety Precautions Before Starting the Repair

When working on an engine, it’s important to prioritize safety. Here are some safety precautions to keep in mind:

Before diving into the repair process, it is crucial to ensure that you have taken all the necessary safety measures. Engine repair can be a complex and potentially hazardous task, so it is essential to protect yourself and those around you.

Protective Gear for Engine Repair

One of the first safety precautions to consider is wearing the appropriate protective gear. This includes protective gloves, safety glasses, and a face mask. These items will shield you from any debris that may fly off during the repair process, reducing the risk of eye injuries, cuts, or exposure to harmful substances.

Protective gloves, made from durable materials such as leather or synthetic materials, provide a barrier between your hands and sharp engine components. Safety glasses, on the other hand, safeguard your eyes from any flying particles or chemical splashes that may occur during the repair. Lastly, a face mask will protect you from inhaling harmful fumes or dust that may be present in the engine area.

Safe Handling of Engine Components

Another crucial safety precaution is to always disconnect the battery before working on the engine. This step is essential to prevent any accidental electrical shocks or short circuits that could occur while handling the engine components. It is important to follow the manufacturer’s instructions on how to properly disconnect the battery to ensure your safety.

Furthermore, when working on an engine, it is essential to be cautious when handling hot engine components. The engine can reach extremely high temperatures, and touching hot surfaces can lead to severe burns. To avoid any accidents, it is recommended to let the engine cool down before starting the repair. Additionally, using a sturdy support, such as an engine stand or a jack, will provide stability and prevent any unexpected movements or falls while working on the engine.

By following these safety precautions, you can minimize the risk of accidents and injuries during the engine repair process. Remember, safety should always be a top priority when working with machinery, especially when dealing with complex systems like an engine.

Step-by-Step Guide to Fixing a Lifter Tick

Now that we have our tools and safety precautions in place, let’s dive into the step-by-step process of fixing a lifter tick in a 5.3 engine:

Diagnosing the Lifter Tick

The first step is to confirm that the ticking sound is indeed coming from a lifter. You can use a stethoscope or a long screwdriver to listen for the ticking noise. Place the end of the screwdriver on different parts of the engine, such as the valve covers or the intake manifold, and listen for any abnormal sounds. Once you have confirmed the source of the noise, you can proceed with the repair.

It’s important to note that lifter ticks are often caused by a lack of lubrication or excessive wear. This can happen due to old or contaminated engine oil, or if the lifters themselves are worn out. By diagnosing the lifter tick, you can determine the root cause of the problem and take appropriate action.

Preparing the Engine for Repair

Start by draining the engine oil and removing the oil filter. This will ensure that you have a clean working environment and prevent any oil spills during the repair process. It’s a good idea to have an oil pan handy to collect the drained oil.

Next, remove any components that are blocking your access to the lifters, such as the intake manifold or valve covers. This may require the use of specific tools, such as a socket wrench or a screwdriver, depending on the design of your engine. Take your time and be careful not to damage any surrounding components.

Once you have removed the necessary components, take a moment to inspect them for any signs of wear or damage. This is also a good opportunity to clean any dirt or debris that may have accumulated in these areas. A clean working environment will ensure that your repair is successful and prevent any further issues down the line.

Detailed Repair Process

With the engine prepared, you can now proceed with the repair process. Start by removing the affected lifters using a lifter removal tool. Carefully position the tool over the lifter and apply gentle pressure to release it from its position. Take note of the lifter’s orientation and keep track of which lifter came from which location.

Once you have removed the lifters, inspect them for any signs of wear or damage. Pay close attention to the roller and the pushrod seat, as these are common areas of concern. If you notice any excessive wear or damage, it is recommended to replace the lifters with new ones. This will ensure optimal performance and prevent any future lifter tick issues.

Before reinstalling the lifters, it’s important to clean the lifter bores and the surrounding areas. Use a lint-free cloth or a clean rag to wipe away any dirt or debris. This will ensure a proper fit and prevent any contamination that could affect the lifter’s performance.

Once the lifters are clean, carefully reinstall them in their original positions. Make sure to align the pushrod seat with the pushrod and the roller with the camshaft lobe. Take your time and be gentle to avoid any damage to the lifters or surrounding components.

After reinstalling the lifters, it’s time to put everything back together. Reinstall any components that were removed earlier, such as the intake manifold or valve covers. Make sure to follow the manufacturer’s specifications and torque all bolts to the recommended values. This will ensure a proper seal and prevent any leaks or further issues.

Once everything is back in place, it’s time to refill the engine with fresh oil. Use the recommended oil type and fill it to the appropriate level. Start the engine and listen for any abnormal sounds. If the lifter tick has been successfully fixed, you should notice a significant improvement in engine noise.

Remember to monitor your engine’s performance and listen for any unusual sounds in the days following the repair. Regular maintenance, such as oil changes and inspections, will help prevent lifter tick issues in the future and keep your engine running smoothly.

Post-Repair Steps and Maintenance

After fixing the lifter tick, there are a few important steps to take to ensure everything is functioning correctly:

Checking the Engine After Repair

Start the engine and listen carefully for any abnormal noises. If the lifter tick is gone, you have successfully fixed the issue. However, if the noise persists, further inspection may be required.

Regular Maintenance to Prevent Lifter Tick

To prevent lifter tick from occurring in the future, it’s crucial to follow the manufacturer’s recommended maintenance schedule. Regular oil changes and using high-quality oil will help keep the lifters in good condition.

By following this guide, you can successfully fix a lifter tick in a 5.3 engine. Remember to take your time, use the right tools, and prioritize safety throughout the repair process. With proper maintenance, your engine will run smoothly and quietly for miles to come.