Belts are important accessories that not only hold up our pants but also add a touch of style to our outfits. However, over time, the belt loops on our favorite pants can become worn or damaged, causing frustration and disappointment. If you’re tired of dealing with a broken belt loop, fear not! In this article, we will guide you through the process of fixing a broken belt loop step by step. Whether you’re a seasoned DIY enthusiast or a novice, this guide will help you restore your belt loops and get your favorite pants back in action.

Understanding the Anatomy of a Belt Loop

Before we dive into the repair process, let’s take a moment to understand the structure of a belt loop. Belt loops are small fabric strips that are sewn onto the waistband of pants. Their purpose is to hold the belt securely in place and prevent it from sliding around while you’re wearing it.

A belt loop typically consists of two main components: the loop itself and the attachment points. The loop is a cylindrical-shaped fabric strip that runs vertically along the waistband, encircling the belt. The attachment points, also known as anchors, are the ends of the loop that are securely sewn onto the waistband.

Now, let’s delve deeper into the basic components of a belt loop. The loop is usually made of the same fabric as the pants, ensuring a seamless and cohesive look. It is carefully stitched to create a sturdy and durable structure. The size and width of the loop may vary depending on the style and design of the pants. Some loops are wider and more prominent, while others are narrower and more discreet.

When it comes to the attachment points, they are crucial for the functionality of the belt loop. These points are typically reinforced with extra stitching to withstand the tension and pressure exerted by the belt. The attachment points are strategically positioned on the waistband to provide optimal support and stability.

Basic Components of a Belt Loop

To repair a broken belt loop, it’s crucial to understand the basic components involved. The loop should be intact but detached from the waistband, while the attachment points may be torn, frayed, or completely detached. By identifying these components, you’ll be better equipped to fix the problem effectively.

When repairing a belt loop, it’s important to consider the type of fabric used in the pants. Different fabrics require different repair techniques. For example, if the pants are made of denim, you may need to use a heavy-duty needle and thread to ensure a strong and secure repair. On the other hand, if the pants are made of a delicate fabric like silk or satin, you’ll need to handle them with extra care to avoid causing further damage.

How Belt Loops Function

Now that we have a good grasp of the components, let’s explore how belt loops function. Belt loops are strategically placed along the waistband to evenly distribute the weight of the belt. This not only ensures a secure fit but also prevents the pants from sagging or sliding down. Additionally, they aid in keeping the belt aligned properly, so it doesn’t shift or become twisted during wear.

When you wear a belt, the loop acts as a guide, keeping the belt in place and preventing it from slipping out of position. This is especially important when you’re engaged in physical activities or constantly moving throughout the day. Without properly functioning belt loops, your belt may become loose, causing discomfort and inconvenience.

By understanding the purpose of belt loops, you’ll appreciate their importance and be motivated to repair them promptly to avoid any inconvenience or fashion mishaps. Taking care of your belt loops not only ensures the longevity of your pants but also enhances your overall style and comfort.

Identifying the Problem with Your Belt Loop

Now that you have a solid understanding of the structure and function of belt loops, it’s time to identify the specific problem you’re facing. Belt loops can encounter various issues, so pinpointing the problem will help us determine the appropriate repair method.

But before we delve into the nitty-gritty of belt loop problems, let’s take a moment to appreciate the versatility and importance of belt loops in our daily lives. Belt loops not only serve as functional attachments to keep our belts in place, but they also add a touch of style and sophistication to our outfits. From jeans to trousers, skirts to shorts, belt loops are a ubiquitous feature in our wardrobe.

Common Issues with Belt Loops

One of the most common problems with belt loops is the tearing or fraying of the attachment points. Over time, excessive stress or poor stitching can cause the loops to detach from the waistband, rendering them useless.

Imagine this scenario: you’re getting ready for an important meeting, and as you try to fasten your belt, you notice that one of the loops has come undone. Panic sets in as you realize that without a functional belt loop, your outfit lacks the finishing touch it needs to exude professionalism and confidence.

Another issue to look out for is a completely broken loop. This can occur when pulling a belt through the loop too forcefully, causing it to snap or weaken over time.

Picture this: you’re in a rush to catch your morning train, and in your haste, you tug at your belt with a little too much vigor. Suddenly, you hear a distinct “snap” as the loop gives way, leaving you with a dangling belt and a sense of frustration.

Regardless of the specific problem you’re facing, rest assured that with the right tools and materials, you’ll be able to fix your belt loop and restore it to its former glory.

Assessing the Damage

Before we proceed with the repair process, it’s important to assess the extent of the damage to your belt loop. Carefully examine the attachment points for any signs of tearing, fraying, or detachment. If the loop itself is broken, check for any sharp edges or potential hazards that need to be addressed.

As you inspect the damage, take a moment to reflect on the journey your belt loop has been through. It has been with you through countless adventures, holding your belt securely as you conquered mountains, danced at weddings, and strolled through city streets. It has witnessed your triumphs and supported you through your lows.

Assessing the damage will help you form a clear plan of action and ensure that you’re adequately equipped to tackle the repair process. Remember, a belt loop is not just a mere accessory; it’s a symbol of resilience and reliability.

Gathering the Necessary Tools and Materials

Now that we know what we’re up against, it’s time to gather the tools and materials required for the repair process. Having everything prepared in advance will save you time and ensure a smoother experience.

Tools Needed for Belt Loop Repair

To fix a broken belt loop, you’ll need the following tools:

- Needle

- Thread (matching the color of your pants)

- Scissors

- Safety pins

- Sewing machine (optional)

These tools will enable you to securely reattach the loop and reinforce it, ensuring a long-lasting repair.

Choosing the Right Materials

When it comes to the materials needed for belt loop repair, it’s essential to choose high-quality options that will withstand regular use and maintain the integrity of the loop. Opt for a sturdy thread that matches the color of your pants, as this will ensure a seamless repair.

Additionally, consider the material of the loop itself. If your pants have a denim waistband, you may want to choose a denim fabric strip as a replacement to maintain a cohesive appearance. However, if your pants have a different fabric, opt for a similar material or a sturdy alternative that will withstand daily wear and tear.

Preparing for the Repair Process

Now that we have all the necessary tools and materials ready, it’s important to prepare for the repair process. Establishing an organized and safe workspace will enhance your efficiency and minimize the risk of any mishaps.

Setting Up Your Workspace

Find a well-lit area in your home where you can comfortably work on your pants without any distractions. Ensure that you have a flat surface to lay out your pants, as well as adequate space to maneuver around.

Consider using a clean towel or a padded surface to protect your pants from any potential damage during the repair process.

Safety Measures to Consider

When working with needles, scissors, and sewing machines, it’s important to prioritize safety. Ensure that your workspace is free of any tripping hazards and that you have good lighting to prevent accidental injuries. It’s also a good idea to keep a first aid kit nearby, just in case.

Furthermore, take breaks as needed to avoid straining your eyes or experiencing any discomfort. Remember, patience is key to achieving a successful repair!

Step-by-Step Process to Fix a Broken Belt Loop

Now that we’re fully prepared, let’s dive into the step-by-step process of fixing a broken belt loop. Follow these instructions carefully to restore your belt loops to their former glory.

Removing the Damaged Belt Loop

To begin the repair process, start by gently removing the broken belt loop from the waistband. If the attachment points are completely torn or frayed, there may be no need to remove the loop itself, but rather focus on reattaching it securely.

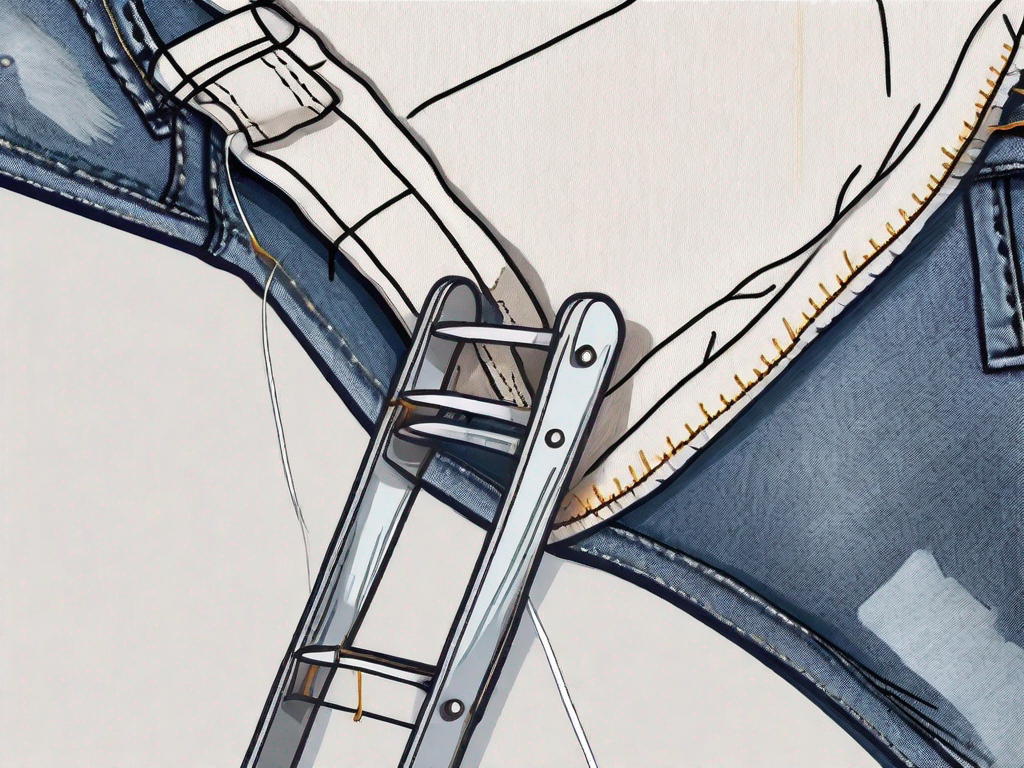

Use scissors or a seam ripper to carefully detach the loop from the waistband. Take your time and be cautious to avoid any accidental snags or damage to the garment.

Once the loop is detached, set it aside, and proceed to the next step of the repair process.

Sewing the New Belt Loop

Now that the damaged loop has been removed, it’s time to sew the replacement loop onto the waistband. Take your new fabric strip and fold it in half lengthwise, with the right sides facing each other.

Align the folded edge of the strip with the waistband, ensuring that it is centered and positioned where the previous loop was located. Pin the fabric strip in place using safety pins, securing it to the waistband.

Next, thread your needle with the chosen thread and tie a knot at the end. Starting at one end of the fabric strip, begin sewing along the folded edge, securing the loop to the waistband. Use small and tight stitches to ensure a strong attachment.

Continue sewing along the entire length of the strip, making sure to secure the ends of the loop as well. Once you reach the end, tie a knot to secure the thread, and trim any excess thread.

Reinforcing the Belt Loop

To ensure the longevity of your repair, it’s important to reinforce the newly attached loop. This will prevent it from tearing or detaching in the future.

Using the same thread and needle, sew a few stitches horizontally across the loop, approximately half an inch above the attachment points. This will create an additional layer of security, strengthening the loop and minimizing the risk of future damage.

Once you’ve reinforced the loop, trim any excess threads, and give your repair work a final visual inspection to ensure everything is neatly in place.

With the completion of these three steps, you have successfully fixed a broken belt loop! Take a moment to admire your handiwork and congratulate yourself on a job well done.

Remember, repairing a belt loop is a valuable skill that can save you time and money. With some practice and patience, you’ll be able to tackle belt loop repairs confidently, ensuring that your favorite pants remain functional and stylish for years to come.

Now go ahead and confidently wear your repaired pants, knowing that you possess the knowledge and skills to fix any belt loop mishaps that may arise in the future!